case - potop-lab.com

EVA Film--Cast Film Extruder

Overview

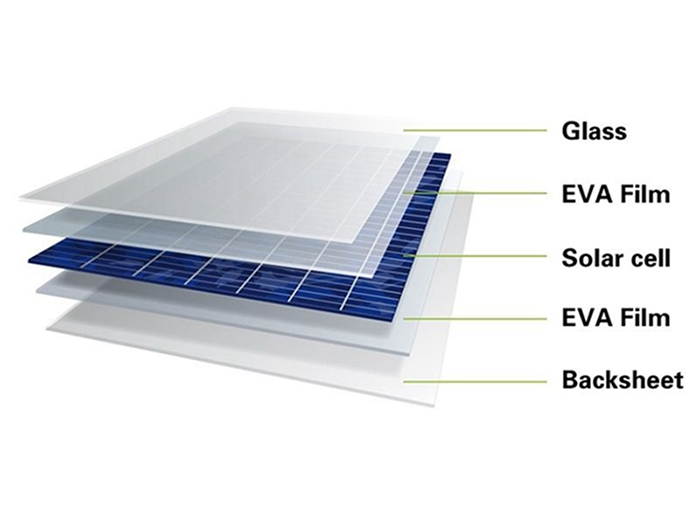

EVA photovoltaic adhesive film is a kind of thermosetting adhesive film with adhesive strength, which is mainly used in the middle of laminated glass, such as the encapsulation of photovoltaic power generation panels. It has the advantages of high transparency, high adhesion, good durability and easy storage.

EVA photovoltaic adhesive film has the following characteristics:

1. High transparency: it can make the light pass through better, so as to improve the power generation efficiency of photovoltaic cells.

2. High adhesion: it can firmly bond the glass and silicon wafers on the photovoltaic power generation panels together and enhance their stability.

3. Good durability: it can resist harsh environmental conditions such as high temperature, humidity and ultraviolet rays, which significantly improves the service life of photovoltaic panels.

4. Easy to store: stored at room temperature, EVA's adhesion is not affected by humidity and water-absorbent film.

5. Stronger sound insulation compared to PVB: especially for high frequency sound effects.

6. Low melting point, easy to flow: it can be applied to all kinds of glass lamination process, such as embossed glass, tempered glass, bending glass and so on.

With the continuous optimization of the preparation process and formula of EVA adhesive film by researchers, it is necessary to use precise and safe laboratory equipment - cast film extrusion equipment to help the development of EVA adhesive film. Guangzhou POTOP for customers customized photovoltaic encapsulation film EVA material customized cast film extruder to meet customer needs, extrusion casting film out of normal, smooth traction, winding and unwinding stable tension, line speed synchronization.

POTOP adopts precise and mature casting technology to prepare EVA film with uniform thickness and no wrinkle crystal point. Because of the elasticity and viscosity of EVA material, it is recommended to use cold water machine to cool down the casting rollers better, and change the mirror rollers to matte matte rollers, so that the casting film can be peeled off better.